山東電纜橋架通用蓋板技術(shù)解析與應(yīng)用指南

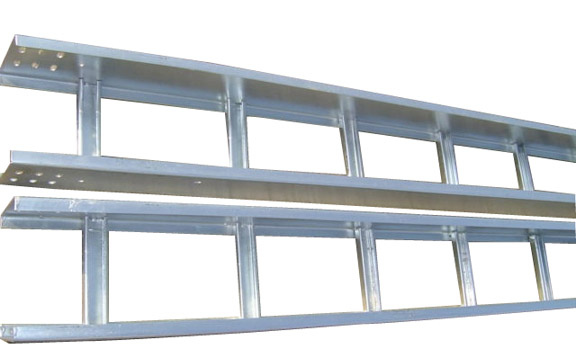

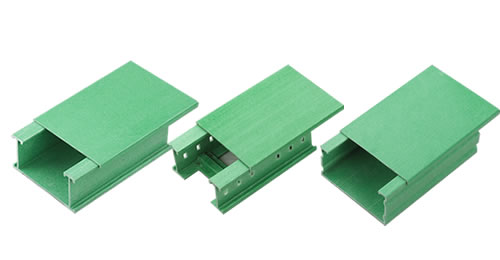

電纜橋架作為電力與通信線(xiàn)路的載體,其蓋板設(shè)計(jì)直接影響系統(tǒng)性、維護(hù)便捷性及環(huán)境適應(yīng)性。通用蓋板以標(biāo)準(zhǔn)化接口、模塊化結(jié)構(gòu)為核心特征,廣泛應(yīng)用于工業(yè)廠(chǎng)房、商業(yè)建筑及基礎(chǔ)設(shè)施領(lǐng)域,成為現(xiàn)代線(xiàn)纜管理的重要組件。

As the carrier of power and communication lines, the cover plate design of cable trays directly affects system safety, maintenance convenience, and environmental adaptability. Universal cover plates are characterized by standardized interfaces and modular structures, and are widely used in industrial plants, commercial buildings, and infrastructure fields, becoming an important component of modern cable management.

一、通用蓋板的技術(shù)特性

1、 Technical characteristics of universal cover plate

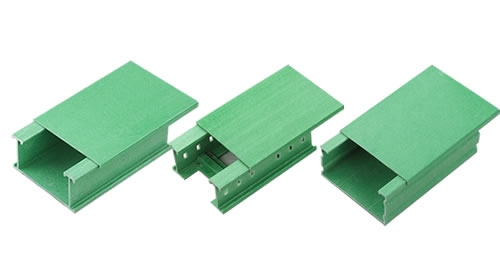

材料兼容性:采用冷軋鋼板、鋁合金或玻璃鋼等材質(zhì),滿(mǎn)足不同場(chǎng)景需求。例如,冷軋鋼板蓋板通過(guò)鍍鋅處理,鹽霧試驗(yàn)可達(dá)1000小時(shí)不銹蝕;鋁合金蓋板重量減輕,適用于對(duì)荷載敏感的吊裝場(chǎng)景。

Material compatibility: Using cold-rolled steel plates, aluminum alloys, or fiberglass materials to meet the needs of different scenarios. For example, cold-rolled steel plate cover plates can undergo galvanizing treatment and undergo salt spray testing for up to 1000 hours without rusting; Aluminum alloy cover plate reduces weight and is suitable for load sensitive lifting scenarios.

結(jié)構(gòu)標(biāo)準(zhǔn)化:蓋板與橋架本體通過(guò)卡扣或螺栓連接,某企業(yè)標(biāo)準(zhǔn)顯示,其通用接口可適配90%以上橋架型號(hào),減少備件庫(kù)存成本。

Structural standardization: The cover plate and the bridge body are connected by buckles or bolts. According to a certain enterprise standard, its universal interface can adapt to more than 90% of bridge models, reducing spare parts inventory costs.

防護(hù)等級(jí)提升:雙層設(shè)計(jì)結(jié)合密封膠條,實(shí)現(xiàn)IP55防護(hù)等級(jí),某數(shù)據(jù)中心應(yīng)用案例表明,該設(shè)計(jì)使粉塵侵入量降低。

Protection level improvement: The double-layer design combined with sealing strips achieves an IP55 protection level. A data center application case shows that this design reduces the amount of dust intrusion.

二、核心功能設(shè)計(jì)

2、 Core Function Design

快速啟閉機(jī)制:采用彈簧鎖扣或免工具快拆結(jié)構(gòu),單手操作即可完成蓋板開(kāi)合。某醫(yī)院項(xiàng)目統(tǒng)計(jì)顯示,該設(shè)計(jì)使日常巡檢效率提升。

Quick opening and closing mechanism: using spring lock or tool free quick release structure, the cover can be opened and closed with one hand operation. According to statistics from a certain hospital project, this design has improved the efficiency of daily inspections.

散熱優(yōu)化:蓋板表面沖壓散熱孔,孔徑與間距經(jīng)流體仿真優(yōu)化,某測(cè)試顯示,在40℃環(huán)境下可使橋架內(nèi)部溫度降低。

Heat dissipation optimization: Heat dissipation holes are punched on the surface of the cover plate, and the aperture and spacing are optimized through fluid simulation. A certain test shows that the temperature inside the bridge can be reduced at 40 ℃ environment.

承重強(qiáng)化:通過(guò)加強(qiáng)筋與折邊工藝提升抗彎強(qiáng)度,某實(shí)驗(yàn)室數(shù)據(jù)表明,2mm厚鋼板蓋板可承受集中載荷,遠(yuǎn)超行業(yè)標(biāo)準(zhǔn)。

Load bearing strengthening: By strengthening the ribs and folding process, the bending strength is improved. Data from a certain laboratory shows that a 2mm thick steel plate cover can withstand concentrated loads, far exceeding industry standards.

三、典型應(yīng)用場(chǎng)景

3、 Typical application scenarios

工業(yè)環(huán)境:在冶金、化工等腐蝕性場(chǎng)所,采用玻璃鋼蓋板可耐受酸堿侵蝕,某化工廠(chǎng)應(yīng)用5年后,蓋板機(jī)械性能保留率仍達(dá)。

Industrial environment: In corrosive places such as metallurgy and chemical industry, the use of fiberglass cover plates can withstand acid and alkali corrosion. After 5 years of application in a certain chemical plant, the mechanical performance retention rate of the cover plate still reaches.

公共建筑:鋁合金蓋板搭配木紋轉(zhuǎn)印表面處理,某機(jī)場(chǎng)項(xiàng)目通過(guò)該方案實(shí)現(xiàn)與裝飾風(fēng)格的統(tǒng)一,同時(shí)滿(mǎn)足防火要求。

Public buildings: Aluminum alloy cover plates combined with wood grain transfer printing surface treatment, a certain airport project achieved unity with decorative style through this scheme, while meeting fire prevention requirements.

戶(hù)外場(chǎng)景:雙層蓋板設(shè)計(jì)結(jié)合排水坡度,某光伏電站應(yīng)用后,積水殘留量減少,避免線(xiàn)纜長(zhǎng)期浸泡風(fēng)險(xiǎn)。

Outdoor scene: The double-layer cover design combined with drainage slope reduces the residual amount of accumulated water after the application of a certain photovoltaic power station, avoiding the risk of long-term cable immersion.

四、安裝與維護(hù)要點(diǎn)

4、 Key points for installation and maintenance

定位校準(zhǔn):安裝前需檢查橋架本體平整度,誤差超過(guò)2mm/m時(shí)需矯正,否則會(huì)導(dǎo)致蓋板密封失效。

Positioning calibration: Before installation, it is necessary to check the flatness of the bridge body. If the error exceeds 2mm/m, it needs to be corrected, otherwise it will cause the sealing failure of the cover plate.

扭矩控制:螺栓緊固力矩需控制在1.5-2.0N·m,某案例因過(guò)度擰緊導(dǎo)致蓋板變形,產(chǎn)生電磁屏蔽漏洞。

Torque control: The tightening torque of the bolts needs to be controlled between 1.5-2.0 N · m. In a certain case, excessive tightening caused deformation of the cover plate, resulting in electromagnetic shielding vulnerabilities.

定期巡檢:建議每季度檢查鎖扣彈性及密封膠條狀態(tài),某數(shù)據(jù)中心因未及時(shí)發(fā)現(xiàn)膠條老化,導(dǎo)致小動(dòng)物侵入引發(fā)短路。

Regular inspection: It is recommended to check the elasticity of the lock buckle and the condition of the sealing strip every quarter. A data center did not detect the aging of the sealing strip in a timely manner, which led to the intrusion of small animals and caused a short circuit.

五、行業(yè)發(fā)展趨勢(shì)

5、 Industry Development Trends

智能化升級(jí):集成RFID標(biāo)簽或光纖傳感器,實(shí)現(xiàn)蓋板狀態(tài)實(shí)時(shí)監(jiān)測(cè)。某試點(diǎn)項(xiàng)目通過(guò)該技術(shù),使異常開(kāi)啟響應(yīng)時(shí)間縮短30秒內(nèi)。

Intelligent upgrade: Integrate RFID tags or fiber optic sensors to achieve real-time monitoring of cover status. A pilot project has shortened the response time for abnormal opening to 30 seconds through this technology.

綠色材料應(yīng)用:采用再生鋁合金或生物基復(fù)合材料,某企業(yè)產(chǎn)品碳足跡較傳統(tǒng)材料降低,符合歐盟RoHS標(biāo)準(zhǔn)。

Green material application: Using recycled aluminum alloy or biobased composite materials, the carbon footprint of a certain enterprise's products is reduced compared to traditional materials and meets the EU RoHS standard.

預(yù)制化裝配:與BIM技術(shù)結(jié)合,實(shí)現(xiàn)蓋板型號(hào)、孔位預(yù)開(kāi)孔的精準(zhǔn)匹配,某醫(yī)院項(xiàng)目通過(guò)該模式使安裝誤差控制在±1mm以?xún)?nèi)。

Prefabricated assembly: Combined with BIM technology, it achieves precise matching of cover plate models and pre drilled holes. A hospital project has controlled installation errors within ± 1mm through this mode.

電纜橋架通用蓋板通過(guò)材料科學(xué)、結(jié)構(gòu)力學(xué)及智能制造的融合,構(gòu)建起、、的線(xiàn)纜防護(hù)體系。其標(biāo)準(zhǔn)化設(shè)計(jì)不僅降低了全生命周期成本,更為智慧建筑、智能工廠(chǎng)等場(chǎng)景提供了可擴(kuò)展的基礎(chǔ)設(shè)施平臺(tái)。隨著物聯(lián)網(wǎng)與綠色建材技術(shù)的深入應(yīng)用,未來(lái)蓋板系統(tǒng)將向“主動(dòng)防護(hù)、智能互聯(lián)”方向持續(xù)演進(jìn)。

The universal cover plate for cable trays integrates material science, structural mechanics, and intelligent manufacturing to construct an efficient, safe, and environmentally friendly cable protection system. Its standardized design not only reduces the full lifecycle cost, but also provides a scalable infrastructure platform for scenarios such as smart buildings and smart factories. With the deepening application of the Internet of Things and green building materials technology, the future cover system will continue to evolve towards the direction of "active protection and intelligent interconnection".

本文由山東電纜橋架友情奉獻(xiàn).更多有關(guān)的知識(shí)請(qǐng)點(diǎn)擊 http://m.bjxmj.com 真誠(chéng)的態(tài)度.為您提供為的服務(wù).更多有關(guān)的知識(shí)我們將會(huì)陸續(xù)向大家奉獻(xiàn).敬請(qǐng)期待.

This article is a friendly contribution from Jinan Cable Bridge For more related knowledge, please click http://m.bjxmj.com Sincere attitude To provide you with comprehensive services We will gradually contribute more relevant knowledge to everyone Coming soon.山東電纜橋架

下一篇:電纜橋架鏈接件的多樣化連接方式解析

相關(guān)文章 / Recommended news

- 山東電纜橋架:潮濕環(huán)境如地下室衛(wèi)生間該選哪種材質(zhì)的橋架

- 電纜橋架是什么?主要用于哪些場(chǎng)景?

- 3分鐘搞懂電纜橋架接地那些事兒

- 如何確定適合的電纜橋架結(jié)構(gòu)形式

- 山東電纜橋架:金屬線(xiàn)槽橋架安裝工藝要點(diǎn)!

- 濟(jì)南電纜橋架:電纜橋架常用的安裝方式及安裝單價(jià)分享

- 山東電纜橋架:設(shè)計(jì)施工時(shí)金屬橋架怎么接地?

- 濟(jì)南電纜橋架:橋架外形尺寸允許偏差要求

- 山東電纜橋架:一文讀懂國(guó)標(biāo)電纜橋架厚度規(guī)定

- 濟(jì)南電纜橋架:關(guān)于電纜橋架接地問(wèn)題應(yīng)對(duì)措施