濟南電纜橋架:不同材質(zhì)的電纜橋架各自有哪些性能特點

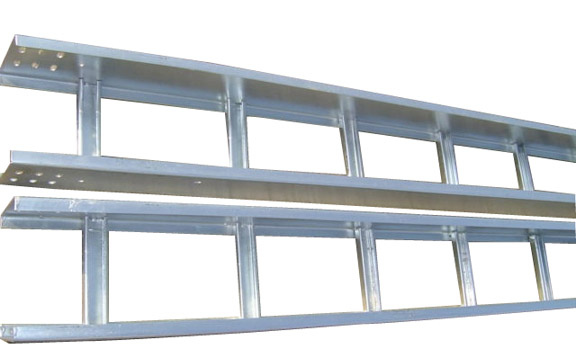

工程中電纜橋架是電氣安裝常用的材質(zhì)設(shè)施,以敷設(shè)線纜多、施工方便而優(yōu)于管道,尤其在系統(tǒng)干線,集中布線的場合更加體現(xiàn)其優(yōu)越性。橋架的形式有槽式、托盤式、梯架式等多種。橋架也有很多種材質(zhì)和不同類型的工藝,比如材質(zhì)分為:不銹鋼、鋁合金、玻璃鋼等材質(zhì);工藝分為:熱鍍鋅、靜電噴塑、鍍鋅等工藝;另外按消防要求還有防火與耐火的橋架。每種材質(zhì)和工藝的性能特點都是不同的,電纜橋架主要用途是用來支撐電纜、保護電纜以及管理電纜的,給我們的電纜線路管理帶來了很大的方便。

Cable trays are commonly used materials and facilities for electrical installation in engineering. They are superior to pipelines in terms of laying more cables and convenient construction, especially in the case of system trunk lines and centralized wiring, which further demonstrates their superiority. There are various forms of cable trays, such as trough type, tray type, ladder type, etc. There are also many types of materials and techniques for bridge frames, such as stainless steel, aluminum alloy, fiberglass, and other materials; The process is divided into: hot-dip galvanizing, electrostatic spraying, galvanizing and other processes; In addition, according to fire safety requirements, there are fire-resistant and fire-resistant cable trays. The performance characteristics of each material and process are different. Cable trays are mainly used to support cables, protect cables, and manage cables, which brings great convenience to our cable line management.

一、鍍鋅橋架與熱鍍鋅橋架(熱浸鋅橋架)區(qū)別

1、 Difference between galvanized bridge and hot-dip galvanized bridge (hot-dip galvanized bridge)

鍍鋅橋架:鍍鋅橋架又名電鍍鋅橋架;一般人理解為鍍鋅橋架以為是熱鍍鋅橋架,其實是不對的,跟鍍鋅管一樣,橋架的鍍鋅也分兩種,即冷鍍鋅(電鍍鋅)和熱鍍鋅(熱浸鍍鋅);

Galvanized bridge: Galvanized bridge, also known as electroplated galvanized bridge; The general understanding of galvanized cable trays as hot-dip galvanized cable trays is actually incorrect. Like galvanized pipes, there are two types of galvanizing for cable trays, namely cold galvanizing (electro galvanizing) and hot-dip galvanizing (hot-dip galvanizing);

鋼鐵在空氣、水或土壤中很容易生銹,甚完全損壞。每年因腐蝕造成的鋼鐵損失約占整個鋼鐵產(chǎn)量的1/10,另一方面,為使鋼鐵制品與零件表面具有某種特殊功能,同時賦予其表面裝飾性的外觀,所以,一般采用電鍍鋅的方式對其處理。

Steel is prone to rusting and even complete damage in air, water, or soil. The annual steel loss caused by corrosion accounts for about 1/10 of the entire steel production. On the other hand, in order to give steel products and parts a special function on the surface and give them a decorative appearance, electroplating is generally used for treatment.

由于鋅在干燥空氣中不易變化,而在潮濕的空氣中,表面能生成一種很致密的堿式碳酸鋅薄膜,這種薄膜能有效保護內(nèi)部不再受到腐蝕。并且當某種原因,使鍍層發(fā)生破壞而露出不太大的鋼基時,鋅與鋼基體形成微電池,使鋼基體成為陰極而受到保護。

Due to the fact that zinc is not easily changed in dry air, while in humid air, a very dense basic zinc carbonate film can be formed on the surface, which can effectively protect the interior from corrosion. And when for some reason, the coating is damaged and a relatively small steel substrate is exposed, zinc forms a microbattery with the steel substrate, making the steel substrate a cathode and protected.

2、性能特點:

2. Performance characteristics:

1)鋅鍍層較厚,結(jié)晶細致、均勻且無孔隙,抗腐蝕性良好;2)電鍍所得鋅層較純,在酸、堿等霧氣中腐蝕較慢,能有效保護鋼基體;3)鋅鍍層經(jīng)鉻酸鈍化后形成白色、彩色、軍綠色等,美觀大方,具有一定的裝飾性;4)由于鋅鍍層具有良好的延展性,因此可進行冷沖、軋制、折彎等各種成型而不損壞鍍層。熱鍍鋅橋架(熱浸鋅橋架)1、熱浸鋅說明:

1) The zinc coating is thick, with fine and uniform crystallization and no pores, and has good corrosion resistance; 2) The zinc layer obtained by electroplating is relatively pure and corrodes slowly in acid, alkali and other mist, which can effectively protect the steel substrate; 3) After chromic acid passivation, the zinc coating forms white, colored, military green, etc., which are aesthetically pleasing and have a certain degree of decorative value; 4) Due to its excellent ductility, zinc coating can be formed through various processes such as cold stamping, rolling, bending, etc. without damaging the coating. Hot dip galvanized bridge (hot-dip galvanized bridge) 1. Hot dip galvanizing instructions:

在各種保護鋼基體的涂鍍方法中,熱浸鋅是非常優(yōu)良的一種。它是在鋅呈液體的狀態(tài)下,經(jīng)過了相當復(fù)雜的物理、化學作用之后,在鋼鐵上不僅鍍上較厚的純鋅層,而且還生成一種鋅一鐵合金層。這種鍍法,不僅具備了電鍍鋅的耐腐蝕特點,而且由于具有鋅鐵合金層。還具有電鍍鋅所無法相比擬的強耐蝕性。因此這種鍍法特別適用于各種強酸、堿霧氣等強腐蝕環(huán)境中。

Among various coating methods for protecting steel substrates, hot-dip galvanizing is an excellent one. It is a process in which zinc is in a liquid state and undergoes complex physical and chemical reactions, resulting in the deposition of a thick layer of pure zinc on steel and the formation of a zinc iron alloy layer. This plating method not only has the corrosion resistance characteristics of electroplated zinc, but also has a zinc iron alloy layer. It also has strong corrosion resistance that cannot be compared to electroplated zinc. Therefore, this plating method is particularly suitable for various strong acid, alkali mist and other highly corrosive environments.

2、原理:熱浸鋅層是鋅在高溫液態(tài)下,分三個步驟形成的:

2. Principle: The hot-dip zinc layer is formed by zinc in a high-temperature liquid state in three steps:

1)鐵基表面被鋅液溶解形成鋅—鐵合金相層;

1) The iron-based surface is dissolved by zinc solution to form a zinc iron alloy phase layer;

2)合金層中的鋅離子進一步向基體擴散形成鋅鐵互溶層;3)合金層表面包絡(luò)著鋅層。3、性能特點:

2) The zinc ions in the alloy layer further diffuse into the matrix to form a zinc iron miscible layer; 3) The surface of the alloy layer is enveloped by a zinc layer. 3. Performance characteristics:

(1) 具有較厚的致密的純鋅層覆蓋在鋼鐵表面上,它可以避免鋼鐵基體與任何的腐蝕溶液的接觸,保護鋼基體免受腐蝕。在一般大氣中,鋅層表面形成一層很薄而密實的氧化鋅層表面,它很難溶于水,故對鋼基體起著一定保護作用。如果氧化鋅與大氣中其它成分生成不溶性鋅鹽后,則防蝕作用更理想。(2) 有鐵—鋅合金層,結(jié)合致密,在海洋性鹽霧大氣及工業(yè)性大氣中表現(xiàn)特有抗腐蝕性;(3) 由于結(jié)合牢固,鋅—鐵互溶,具有很強的耐磨性;(4) 由于鋅具有良好的延展性,其合金層與鋼基附著牢固,因此熱鍍件可進行冷沖、軋制、拉絲、彎曲等各種成型而不損壞鍍層;(5) 鋼結(jié)構(gòu)件熱鍍鋅后,相當于一次退火處理,能有效改善鋼基體的機械性能,鋼件成型焊接時的應(yīng)力,有利于對鋼結(jié)構(gòu)件進行車削加工。(6) 熱鍍鋅后的配件表面光亮美觀。(7) 純鋅層是熱鍍鋅中富有塑性的一層鍍鋅層,其性質(zhì)基本接近于純鋅,具有延展性,所以它富于撓性。二、噴塑橋架和鍍鋅橋架的區(qū)別

(1) A thick and dense pure zinc layer covers the surface of the steel, which can prevent the steel substrate from coming into contact with any corrosive solution and protect the steel substrate from corrosion. In the general atmosphere, a thin and dense layer of zinc oxide is formed on the surface of the zinc layer, which is difficult to dissolve in water and therefore plays a certain protective role on the steel substrate. If zinc oxide forms insoluble zinc salts with other components in the atmosphere, the anti-corrosion effect is more ideal. (2) There is an iron zinc alloy layer, which is dense and exhibits unique corrosion resistance in marine salt spray and industrial atmospheres; (3) Due to its strong bonding and zinc iron compatibility, it has strong wear resistance; (4) Due to the excellent ductility of zinc, its alloy layer adheres firmly to the steel substrate, allowing hot-dip plated parts to be formed through various processes such as cold stamping, rolling, drawing, and bending without damaging the coating; (5) After hot-dip galvanizing of steel structural components, it is equivalent to one annealing treatment, which can effectively improve the mechanical properties of the steel substrate, eliminate the stress during the forming and welding of steel components, and facilitate the turning processing of steel structural components. (6) The surface of the accessories after hot-dip galvanizing is bright and beautiful. (7) The pure zinc layer is the most plastic layer of hot-dip galvanizing, with properties similar to pure zinc and ductility, making it flexible. 2、 The difference between spray painted bridge and galvanized bridge

噴塑橋架跟鍍鋅橋架只是工藝上不一樣,橋架的規(guī)格、型號、形狀結(jié)構(gòu)都是一模一樣的。

Sprayed plastic cable tray is different from galvanized cable tray in technology, and the specification, model, shape and structure of cable tray are identical.

噴塑橋架和鍍鋅橋架工藝區(qū)別:鍍鋅橋架跟噴塑橋架都屬于金屬電纜橋架,鍍鋅橋架是用鍍鋅鋼板制造而成,鍍鋅板相信不用過多解釋,而噴塑橋架則是用鍍鋅橋架拿去加工噴塑一層靜電噴涂層在表面上,所以叫噴塑橋架,簡單理解就是噴塑橋架是鍍鋅橋架的升級版,防腐蝕性能更強。鍍鋅橋架

The difference between spray painted cable tray and galvanized cable tray technology: Firstly, galvanized cable tray and spray painted cable tray both belong to metal cable tray. Galvanized cable tray is made of galvanized steel plate, which I believe does not require too much explanation. On the other hand, spray painted cable tray is processed by spraying a layer of electrostatic spray coating on the surface of galvanized cable tray, so it is called spray painted cable tray. Simply put, spray painted cable tray is an upgraded version of galvanized cable tray with stronger anti-corrosion performance. galvanized cable tray

噴塑橋架和鍍鋅橋架的區(qū)別還有一點:就是上也不同,噴塑橋架既然是鍍鋅橋架的升級版,耐腐蝕性更強,當然也是不一樣的,噴塑橋架比鍍鋅橋架貴。

The difference between spray painted bridge and galvanized bridge is also in terms of price. Since spray painted bridge is an upgraded version of galvanized bridge with stronger corrosion resistance, the price is also different. Spray painted bridge is more expensive than galvanized bridge.

噴塑式橋架

Spray painted bridge frame

三、不銹鋼橋架與鍍鋅橋架有何區(qū)別

3、 What is the difference between stainless steel bridge and galvanized bridge

1、不銹鋼橋架的介紹:

1. Introduction to Stainless Steel Bridge:

不銹鋼橋架采用的是304不銹鋼材質(zhì)經(jīng)過裁剪、折彎制作而成的一種橋架,具有非常耐腐蝕、耐沖擊、不易銹蝕的特點。其中不銹鋼橋架包括槽式橋架、托盤式橋架、梯級式橋架三種類型,不同類型的橋架可以讓不銹鋼材質(zhì)的橋架滿足不同地區(qū)的使用。所以不銹鋼橋架是用來敷設(shè)安裝重腐蝕、潮濕地區(qū)電纜線路的不錯選擇。

The stainless steel bridge is made of 304 stainless steel material that has been cut and bent, and has the characteristics of being very corrosion-resistant, impact resistant, and not easily corroded. Stainless steel cable trays include three types: trough type cable trays, tray type cable trays, and stepped type cable trays. Different types of cable trays can make stainless steel material cable trays meet the needs of different regions. So stainless steel cable trays are a good choice for laying and installing cable lines in heavily corroded and humid areas.

2、鍍鋅橋架的介紹:鍍鋅橋架采用的的冷軋鋼板經(jīng)過裁剪、折彎制作而成的一種橋架,具有很好的耐腐蝕、耐磨損性能。鍍鋅橋架表面的鍍鋅層更加增添了橋架的美觀,使得安裝敷設(shè)后整體效果更加美觀。同時鍍鋅橋架也可以在室外進行安裝敷設(shè)。

2. Introduction to Galvanized Bridge: Galvanized bridge is a type of bridge made by cutting and bending high-quality cold-rolled steel plates, which has excellent corrosion resistance and wear resistance. The galvanized layer on the surface of the galvanized bridge further enhances the aesthetics of the bridge, making the overall effect more beautiful after installation and laying. Galvanized cable trays can also be installed and laid outdoors.

鍍鋅電纜橋架的用途:1)由于鍍鋅電纜橋架具有不錯的性能,可以在重腐蝕的環(huán)境中敷設(shè)安裝。適應(yīng)范圍非常廣泛,且非常的穩(wěn)定。2)在很多工程建筑中也是需要使用到鍍鋅電纜橋架的,可以用鍍鋅電纜橋架來支撐和管理電纜線路,且起到不錯的管理效果。3)在沿海、潮濕地區(qū)使用鍍鋅電纜橋架,可以很好地保護電纜線路不會被腐蝕、和侵蝕。

The purpose of galvanized cable tray: 1) Due to its good performance, galvanized cable tray can be laid and installed in heavily corrosive environments. The adaptability range is very wide, and it is very stable and safe. 2) Galvanized cable trays are also required in many construction projects. Galvanized cable trays can be used to support and manage cable lines, and have a good management effect. 3) The use of galvanized cable trays in coastal and humid areas can effectively protect cable lines from corrosion and erosion.

鍍鋅電纜橋架的優(yōu)勢:1)耐沖擊:鍍鋅電纜橋架的硬度非常強,在遇到重壓力和沖擊都不容易出現(xiàn)變形和扭曲。2)費用低:鍍鋅電纜橋架的工藝處理費用要比其他工藝處理要低一些,且效果不會其他的工藝處理差。3)外觀美:鍍鋅電纜橋架外表非常的光滑平整且明亮,整體呈現(xiàn)非常的美觀。4)省工時:鍍鋅電纜橋架的工藝處理非常的方便簡單,只需要將冷軋鋼板浸泡入液態(tài)鋅中即可,操作既簡單又省力。

Advantages of galvanized cable trays: 1) Impact resistance: Galvanized cable trays have very strong hardness and are not easily deformed or twisted when subjected to heavy pressure and impact. 2) Low cost: The processing cost of galvanized cable trays is slightly lower than other processing methods, and the effect is not inferior to other processing methods. 3) Appearance beauty: The galvanized cable tray has a very smooth, flat and bright appearance, presenting a very beautiful overall appearance. 4) Time saving: The process treatment of galvanized cable trays is very convenient and simple. Simply immerse the cold-rolled steel plate in liquid zinc, making the operation simple and effortless.

如何選購鍍鋅電纜橋架通常我們購買產(chǎn)品的時候都會去仔細了解這個產(chǎn)品的性能特點,所以我們在選購電纜橋架的時候也不能操之過急,需要仔細的去了解各方面的問題,比如說電纜橋架的質(zhì)量如何,我們就需要叫廠家提供電纜橋架質(zhì)量的相關(guān)檢測報告了。還有在合作的時候我們需要注意廠家是否信譽良好,因為誠信才是一個工廠的立足之本,才能使我們更好的合作。總而言之,我們在選購時盡量地去多了解了解相關(guān)的信息。

How to choose a galvanized cable tray? Usually, when we purchase a product, we carefully understand the performance characteristics of the product. Therefore, we cannot be too hasty when choosing a cable tray. We need to carefully understand all aspects, such as the quality of the cable tray. We need to ask the manufacturer to provide relevant inspection reports on the quality of the cable tray. We also need to pay attention to whether the manufacturer has a good reputation when cooperating, because integrity is the foundation of a factory and can enable us to cooperate better. In summary, we should try our best to learn more about relevant information when making a purchase.

3、不銹鋼和鍍鋅橋架的區(qū)別:(1)材質(zhì)不同:一種采用的材質(zhì)是不銹鋼、一種采用的材質(zhì)是冷軋鋼板。(2)不同:由于不銹鋼材質(zhì)的成本很高,所以不銹鋼橋架的要比鍍鋅橋架的貴一些。不過不銹鋼橋架的性能特點、使用壽命要比鍍鋅橋架好一些。(3)工藝不同:不銹鋼橋架是直接采用不銹鋼材質(zhì)制作的,而鍍鋅橋架是采用冷軋鋼板制作而成,然后還需要經(jīng)過一層鍍鋅工藝處理。所以不銹鋼橋架雖然比起鍍鋅橋架成本更高,但不容易生銹。

3. The difference between stainless steel and galvanized cable trays: (1) Different materials: one uses stainless steel and the other uses cold-rolled steel plate. (2) Price difference: Due to the high cost of stainless steel material, the price of stainless steel cable trays is slightly higher than that of galvanized cable trays. However, the performance characteristics and service life of stainless steel cable trays are better than those of galvanized cable trays. (3) Different processes: Stainless steel cable trays are directly made of stainless steel material, while galvanized cable trays are made of cold-rolled steel plates and then require a layer of galvanizing process treatment. So although stainless steel cable trays are more expensive than galvanized cable trays, they are less prone to rusting.

不銹鋼表面處理為:酸洗后拋光,耐蝕性強,適用于室內(nèi)室外。鍍鋅:也稱為冷鍍鋅也叫電鍍鋅,是利用電解設(shè)備將工件經(jīng)過除油、酸洗后放入成分為鋅鹽的溶液中,利用電解設(shè)備電流從正極向負極的定向移動,就會在工件上沉積一層鋅。

The surface treatment of stainless steel is acid washed and polished, with strong corrosion resistance, suitable for indoor and outdoor use. Galvanizing, also known as cold galvanizing or electroplating, is the process of using electrolytic equipment to remove oil and acid from a workpiece, and then placing it in a solution composed of zinc salts. By directing the current of the electrolytic equipment from the positive electrode to the negative electrode, a layer of zinc is deposited on the workpiece.

大家知道,電纜橋架的表面防腐層類別主要有熱浸鋅、鍍鋅鎳、冷鍍鋅、粉末靜電噴涂等方式,生產(chǎn)廠家資料顯示:熱浸鋅工藝壽命不小于40年,適用于室外重腐蝕環(huán)境,造價高;鍍鋅鎳工藝壽命不小于30年,也適用于室外重腐蝕環(huán)境,造價高;冷鍍鋅工藝壽命不小于12年,適用于室外輕腐蝕環(huán)境,造價一般;粉末靜電噴涂工藝壽命不小于12年,適用于室內(nèi)常溫干燥環(huán)境,一般。一般情況下,設(shè)計人員應(yīng)該根據(jù)工程環(huán)境條件合理選擇電纜橋架的表面防腐層類別,并在設(shè)計文件中清晰地表達。

As we all know, the types of surface anti-corrosion coatings for cable trays mainly include hot-dip galvanizing, zinc nickel plating, cold galvanizing, powder electrostatic spraying, etc. According to the manufacturer's information, the hot-dip galvanizing process has a service life of not less than 40 years and is suitable for outdoor heavy corrosion environments with high cost; The service life of galvanized nickel process is not less than 30 years, and it is also suitable for outdoor heavy corrosive environments with high cost; The service life of cold galvanizing process is not less than 12 years, suitable for outdoor light corrosion environment, and the cost is average; The service life of powder electrostatic spraying process is not less than 12 years, suitable for indoor room temperature and dry environment, and the price is average. In general, designers should reasonably select the type of surface anti-corrosion coating for cable trays based on the engineering environmental conditions, and clearly express it in the design documents.

4、不銹鋼和鍍鋅橋架的相同之處:這兩種橋架的性能特點都差不多相同,都是具有不錯的耐腐蝕、耐老化、耐磨損性能,可以很好地保護電纜線路不受到傷害。但是由于不銹鋼的成本過高,所以不銹鋼橋架的采用率就沒有鍍鋅橋架的高,很多用戶選擇的都是鍍鋅橋架。

4. The similarities between stainless steel and galvanized cable trays: Both types of cable trays have similar performance characteristics, including good corrosion resistance, aging resistance, and wear resistance, which can effectively protect cable lines from damage. However, due to the high cost of stainless steel, the adoption rate of stainless steel cable trays is not as high as that of galvanized cable trays, and many users choose galvanized cable trays.

四、防火橋架與鍍鋅橋架有何區(qū)別

4、 What is the difference between fire-resistant bridge and galvanized bridge

主要是防火橋架與鍍鋅橋架兩者用途不同。1、防火橋架適用于10KV以下電力電纜,以及控制電纜、照明配線等室內(nèi)室外架空電纜溝、隧道的敷設(shè)。

The main difference is that fire-resistant cable trays and galvanized cable trays have different purposes. 1. Fireproof cable trays are suitable for laying indoor and outdoor overhead cable trenches and tunnels for power cables below 10KV, as well as control cables, lighting wiring, etc.

防火橋架主要由玻璃纖維增強材料、無機黏合劑復(fù)合的防火板,與金屬骨架復(fù)合以及其他的防火基材組成,外層加防火涂料。防火橋架遇火后不會燃燒,從而阻隔火勢蔓延。防火橋架具有極其良好的防火阻火效果,又具有耐火、耐油、耐腐蝕、、無污染,整體安裝方便等特點。防火涂料有涂層薄、耐火極限高、粘接力強的特點。五、防火橋架和耐火橋架有什么區(qū)別

The fire-resistant bridge is mainly composed of fire-resistant boards reinforced with glass fiber and inorganic adhesives, composite with metal skeleton, and other fire-resistant substrates, with fire-resistant coating added on the outer layer. Fireproof cable trays will not burn when exposed to fire, thus blocking the spread of fire. Fireproof bridge has extremely good fire prevention and extinguishing effects, as well as characteristics such as fire resistance, oil resistance, corrosion resistance, non toxicity, non pollution, and easy overall installation. Fireproof coatings have the characteristics of thin coating, high fire resistance limit, and strong adhesion. 5、 What is the difference between fire-resistant bridge and fire-resistant bridge

防火電纜橋架是現(xiàn)在比較受歡迎的電纜橋架產(chǎn)品,其重要的原因當然就是其具備一定的防火作用。但是防火電纜橋架和耐火電纜橋架確實是兩個非常不同的概念。下面我們就來認識一下,看看如何區(qū)分:

Fireproof cable tray is a popular cable tray product nowadays, and its important reason is of course that it has a certain fireproof effect. But fire-resistant cable trays and fire-resistant cable trays are indeed two very different concepts. Now let's get to know each other and see how to distinguish:

防火橋架:

Fireproof bridge:

主要由玻璃纖維增強材料和無機黏合劑復(fù)合的防火板與金屬骨架復(fù)合以及其他的防火基材組成。采用鋼制外殼,雙層防火蓋板,內(nèi)裝無機防火槽盒 。隔熱層平均厚度為25mm,雙層蓋板通風散熱,內(nèi)噴防火涂料,防火電纜橋架遇火時涂料膨脹,阻塞散熱孔,保護槽盒內(nèi)的電纜。無機防火槽盒防火性能經(jīng)固定耐火檢驗中心所對60分鐘耐火試驗,電纜無損害。支撐的結(jié)構(gòu)性好,可有效地固定無機防火槽盒。 耐火橋架:

The fireproof board is mainly composed of glass fiber reinforced material and inorganic adhesive composite, metal skeleton composite, and other fireproof substrates. Adopting a steel shell, double-layer fireproof cover plate, and inorganic fireproof groove box inside. The average thickness of the insulation layer is 25mm. The double-layer cover plate is ventilated for heat dissipation, and fireproof coating is sprayed inside. When the fireproof cable tray encounters fire, the coating expands, blocking the heat dissipation holes and protecting the cables inside the trough box. The fire resistance performance of the inorganic fireproof trough box has been tested for 60 minutes by the National Fixed Fire Resistance Inspection Center, and the cable has no damage. The supporting structure is good and can effectively fix inorganic fireproof trough boxes. Fire resistant bridge frame:

側(cè)板采用成型機拉制成型,增加了耐火橋架的抗彎強度;側(cè)板和底板采用的技術(shù),表面平整光滑;外表面噴有防火漆,能有效地隔絕空氣,達到隔熱效果;內(nèi)側(cè)墊加硅酸鋁巖棉和防火板,阻止熱量的傳導(dǎo);耐火橋架配有防塵罩,用特殊材料支撐,當發(fā)生火災(zāi)時,防塵罩脫落封死護罩上所有散熱孔,達到防火效果;產(chǎn)品符合防火標準(點擊關(guān)注建筑10大技術(shù)類公眾號)。

The side panels are drawn and formed by a molding machine, which increases the bending strength of the fire-resistant bridge; The side and bottom plates adopt advanced technology, with a smooth and even surface; The outer surface is sprayed with fireproof paint, which can effectively isolate air and achieve thermal insulation effect; Adding aluminum silicate rock wool and fireproof board on the inner side to prevent heat conduction; The fire-resistant bridge is equipped with a dust cover, supported by special materials. In the event of a fire, the dust cover will fall off and seal all the heat dissipation holes on the cover, achieving the effect of fire prevention; The product complies with the national fire protection standard (click on the official account of 10 major technical categories of buildings).

防火橋架指的是結(jié)構(gòu)是由防火材料構(gòu)成或表面涂有防火涂層;而耐火橋架指的是比較經(jīng)燒,不會在短時長的高溫下發(fā)生癱塌或解體;兩者性能都還好,區(qū)別只是成本價錢方面的問題。

Fireproof bridge refers to a structure composed of fire-resistant materials or coated with fire-resistant coatings on the surface; And fire-resistant bridge refers to a relatively durable structure that will not collapse or disintegrate under short-term high temperatures; Both have decent performance, the only difference being in terms of cost and price.

耐火橋架與防火橋架的區(qū)別:外殼結(jié)構(gòu)不同、火燃燒溫度不同、耐火時間不同。1、外殼結(jié)構(gòu)不同:1)耐火橋架:耐火橋架的外殼及隔熱層采用耐高溫≥1100℃的防火材料以及耐高溫≥300℃的絕緣材料。2)防火橋架:防火橋架的外殼加防火隔層,有些外殼涂防火涂料。

The difference between fire-resistant bridge and fire-resistant bridge: different shell structures, different fire combustion temperatures, and different fire-resistant times. 1. Different shell structures: 1) Fire resistant bridge frame: The shell and insulation layer of the fire resistant bridge frame are made of fire-resistant materials with high temperature resistance ≥ 1100 ℃ and insulation materials with high temperature resistance ≥ 300 ℃. 2) Fireproof bridge: The outer shell of the fireproof bridge is equipped with a fireproof partition, and some shells are coated with fireproof paint.

2、火燃燒溫度不同:1)耐火橋架:耐火橋架的火燃燒溫度達到920~1050℃的高溫時才會燃燒。2)防火橋架:防火橋架的火燃燒溫度達到800度左右。

2. The combustion temperature of fire is different: 1) Refractory bridge frame: The fire combustion temperature of refractory bridge frame will only burn when it reaches a high temperature of 920-1050 ℃. 2) Fireproof bridge: The fire combustion temperature of fireproof bridge reaches around 800 degrees.

兩種橋架工藝不同,鋅層厚度不一樣,表面顏色也不同,防火橋架一般為類似電箱的灰色,玻璃鋼橋架為青綠色(重量較輕),很容易區(qū)分。所以兩者的使用壽命不一樣。防火橋架沒有效果,故GB50116-2013標準已經(jīng)沒有金屬線槽需要防火措施這一要求。

The two types of cable trays have different processes, zinc layer thickness, and surface color. Fireproof cable trays are generally gray similar to electrical boxes, while fiberglass cable trays are blue-green (lighter in weight), making them easy to distinguish. So the service life of the two is different. The fire-resistant cable tray is ineffective, so the GB50116-2013 standard no longer requires fire-resistant measures for metal cable trays.

另外,還有采用鋁合金材質(zhì)的鋁合金橋架,玻璃鋼材質(zhì)的玻璃鋼橋架,等等。這里暫不介紹。

In addition, there are aluminum alloy cable trays made of aluminum alloy material, fiberglass cable trays made of fiberglass material, and so on. I won't introduce it here for now.

本文由 濟南電纜橋架 友情奉獻.更多有關(guān)的知識請點擊 http://m.bjxmj.com/ 真誠的態(tài)度.為您提供為的服務(wù).更多有關(guān)的知識我們將會陸續(xù)向大家奉獻.敬請期待.

This article is a friendly contribution from Jinan Cable Bridge For more related knowledge, please click http://m.bjxmj.com/ Sincere attitude To provide you with comprehensive services We will gradually contribute more relevant knowledge to everyone Coming soon.