山東電纜橋架廠家:潮濕地區使用不銹鋼電纜橋架是不錯的選擇

在工程施工中,電力橋架是電氣施工常用的設施,主要用途包括保護電纜、支撐電纜、排列電纜和提供維護通道。通過這些功能,電纜橋架為電纜線束的運行和優化管理提供了可靠的基礎。以敷設線纜多、施工方便而優于管道,尤其在系統干線,集中布線的場合更加體現其優越性。

In engineering construction, power cable trays are commonly used facilities for electrical construction, mainly for protecting cables, supporting cables, arranging cables, and providing maintenance channels. Through these functions, cable trays provide a reliable foundation for the safe operation and optimized management of cable harnesses. It is superior to pipelines in terms of laying more cables and convenient construction, especially in the case of system trunk lines and centralized wiring.

電纜橋架分為槽式、托盤式和梯架式、網格式等結構,由支架、托臂和安裝附件等組成。建筑物內橋架可以獨立架設,也可以敷設在各種建(構)筑物和管廊支架上,應體現結構簡單,造型美觀、配置靈活和維修方便等特點。

Cable trays are divided into trough type, tray type, ladder type, mesh type and other structures, consisting of brackets, support arms and installation accessories. The bridge frame inside the building can be independently erected or laid on various buildings and pipe gallery supports, and should reflect the characteristics of simple structure, beautiful appearance, flexible configuration, and easy maintenance.

根據使用環境和功能要求,我們要選擇相應材質的橋架,電纜橋架的主要材質包括金屬、鋁合金和玻璃鋼。金屬橋架具有強度高、承載能力強和良好的防火性能,適用于各種工業和商業場所,尤其是在對承載要求較高的環境中使用。鋁合金橋架質量輕、外形美觀、耐腐蝕,適用于需要輕量化和美觀要求的場所。玻璃鋼橋架具有良好的耐腐蝕、耐老化和絕緣性能,適用于各種惡劣環境。

According to the usage environment and functional requirements, we need to choose cable trays made of corresponding materials. The main materials for cable trays include metal, aluminum alloy, and fiberglass. Metal cable trays have high strength, strong load-bearing capacity, and good fire resistance, making them suitable for various industrial and commercial places, especially in environments with high load-bearing requirements. Aluminum alloy cable trays are lightweight, aesthetically pleasing, and corrosion-resistant, making them suitable for places that require lightweight and aesthetic requirements. Fiberglass cable trays have good corrosion resistance, aging resistance, and insulation performance, and are suitable for various harsh environments.

一、下面我們就各類材質的橋架特點,給大家簡單介紹一下:

1、 Below, we will briefly introduce the characteristics of cable trays made of various materials:

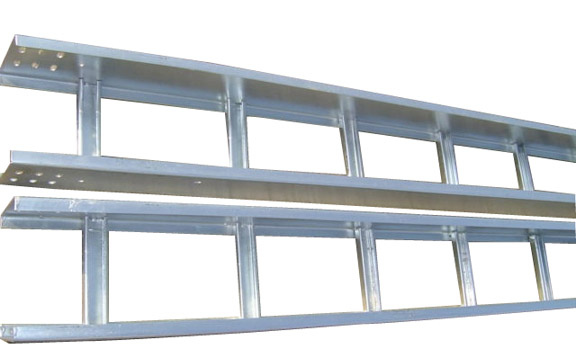

鍍鋅電纜橋架:鍍鋅橋架又名電鍍鋅橋架;橋架的鍍鋅也分兩種,即冷鍍鋅(電鍍鋅)和熱鍍鋅(熱浸鍍鋅);鍍鋅橋架采用的的冷軋鋼板經過裁剪、折彎制作而成的一種橋架,具有很好的耐腐蝕、耐磨損性能。鍍鋅橋架表面的鍍鋅層更加增添了橋架的美觀,使得安裝敷設后整體效果更加美觀。同時鍍鋅橋架也可以在室外進行安裝敷設。特點有:品種全、應用廣、強度大、結構輕、造價低、施工簡單、配線靈活、安裝標準、外型美觀等,適用場景:適用于室內和地下室,具有強度大、結構輕、造價低等優點。

Galvanized cable tray: Galvanized cable tray, also known as electroplated galvanized cable tray; There are also two types of galvanizing for cable trays, namely cold galvanizing (electro galvanizing) and hot-dip galvanizing (hot-dip galvanizing); Galvanized bridge is a type of bridge made by cutting and bending high-quality cold-rolled steel plates, which has excellent corrosion resistance and wear resistance. The galvanized layer on the surface of the galvanized bridge further enhances the aesthetics of the bridge, making the overall effect more beautiful after installation and laying. Galvanized cable trays can also be installed and laid outdoors. Features include: wide variety, wide application, high strength, light structure, low cost, simple construction, flexible wiring, standard installation, beautiful appearance, etc. Applicable scenarios: suitable for indoor and underground use, with advantages such as high strength, light structure, and low cost.

鋁合金電纜橋架:具有外觀漂亮、結構簡單、式樣獨特、荷載能力大、重量輕等特點,表面陽極氧化后,它不但抗腐蝕、還有抗電 磁干擾。適用場景:適用于電廠、化工、石化等各個領域,特別適用于具有高腐蝕環境的場所。

Aluminum alloy cable tray: It has the characteristics of beautiful appearance, simple structure, unique style, high load capacity, and light weight. After surface anodizing, it is not only corrosion-resistant but also resistant to electromagnetic interference. Applicable scenarios: Suitable for various fields such as power plants, chemicals, petrochemicals, etc., especially for places with high corrosion environments.

不銹鋼電纜橋架:不銹鋼橋架采用的是304不銹鋼材質經過裁剪、折彎制作而成的一種橋架,具有非常耐腐蝕、耐沖擊、不易銹蝕的特點。所以不銹鋼橋架是用來敷設安裝重腐蝕、潮濕地區電纜線路的不錯選擇。特點:在各類橋架優越的基礎上,著重在隔熱、散熱、防火方面加以改進,具有非常耐腐蝕、耐沖擊、不易銹蝕的特點,適用場景:適用于電廠、海邊、食品廠、化工廠等環境。

Stainless steel cable tray: The stainless steel cable tray is made of 304 stainless steel material that has been cut and bent, and has the characteristics of being very corrosion-resistant, impact resistant, and not easily corroded. So stainless steel cable trays are a good choice for laying and installing cable lines in heavily corroded and humid areas. Features: On the basis of superior cable trays, emphasis is placed on improving insulation, heat dissipation, and fire prevention. It has the characteristics of being very corrosion-resistant, impact resistant, and not easily corroded. Applicable scenarios: suitable for environments such as power plants, beaches, food factories, chemical plants, etc.

高分子合金電纜橋架:一種新型材料,具有較好的綜合性能。是由多種不同種類的聚合物,采用物理共混或化學接脂的方法,將ABS與PVC等其他輔助材料共混,經過制備工藝創新而制成,產品兼有鋼韌兩種特性。是非金屬防腐型電纜橋架,主要用于高腐蝕性電纜架設的支撐構件。適用場景:由于其本身不生銹、耐強酸弱堿的材料特點,可用在高腐蝕環境(如化工、煤炭、冶金、碼頭等)。玻璃鋼電纜橋架:一種非金屬材料,具有輕質高強、耐腐蝕、耐老化等特點。玻璃鋼電纜橋架既有金屬橋架的剛性,又有玻璃鋼橋架的韌性,耐腐蝕性能好、抗老化性能強。適用場景:能廣泛應用于石油、化工、電力、輕工、電視、電訊等方面。防火橋架:防火橋架主要由玻璃纖維增強材料和無機黏合劑復合的防火板與金屬骨架復合以及其他的防火基材組成。外層加防火涂料,防火橋架遇火后不會燃燒,從而阻隔火勢蔓延,具有極其良好的防火阻火效果,又具有耐火、耐油、耐腐蝕、、無污染,整體安裝方便,結構合理,使用壽命長,并且美觀,電纜安裝在電纜橋架中,環境整潔,清掃方便。防火涂料有涂層薄、耐火極限高、粘接力強的特點。

Polymer alloy cable tray: a new type of material with good comprehensive performance. It is made of various types of polymers, using physical blending or chemical bonding methods to blend ABS with other auxiliary materials such as PVC. Through innovative preparation processes, the product has both steel and toughness characteristics. It is a non-metallic anti-corrosion cable tray mainly used as a supporting component for the installation of highly corrosive cables. Applicable scenarios: Due to its material characteristics of non rusting and resistance to strong acids and weak bases, it can be used in highly corrosive environments (such as chemical, coal, metallurgy, docks, etc.). Fiberglass cable tray: a non-metallic material with characteristics such as lightweight, high strength, corrosion resistance, and aging resistance. Glass fiber reinforced plastic cable tray has both the rigidity of metal tray and the toughness of glass fiber reinforced plastic tray, with good corrosion resistance and aging resistance. Applicable scenarios: It can be widely used in petroleum, chemical, power, light industry, television, telecommunications and other fields. Fireproof bridge: Fireproof bridge is mainly composed of fire-resistant board and metal skeleton composite made of glass fiber reinforced material and inorganic adhesive, as well as other fire-resistant substrates. The outer layer is coated with fire-resistant paint, which prevents the fire-resistant bridge from burning in case of fire, thus blocking the spread of fire. It has extremely good fire-resistant and fire-resistant effects, as well as being fire-resistant, oil resistant, corrosion-resistant, non-toxic, and pollution-free. The overall installation is convenient, the structure is reasonable, the service life is long, and it is beautiful. The cable is installed in the cable bridge, and the environment is clean and easy to clean. Fireproof coatings have the characteristics of thin coating, high fire resistance limit, and strong adhesion.

適用環境:防火橋架是適用于10KV以下電力電纜,以及控制電纜、照明配線等室內室外架空電纜溝、隧道敷設的產品。

Applicable environment: Fireproof cable tray is a product suitable for laying indoor and outdoor overhead cable trenches and tunnels for power cables below 10KV, as well as control cables, lighting wiring, and other indoor and outdoor overhead cables.

二、幾種常用材質的橋架區別

2、 Difference between several commonly used bridge materials

1、冷(電)鍍鋅橋架和熱鍍鋅橋架的區別生成原理冷鍍鋅:冷鍍鋅是將鋼材質或產品在鋅的溶液里浸泡或電解,導致材質或產品表面有一層比較薄的鋅。這種方法是通過電化學原理在鋼鐵器件上沉積一層鋅。熱鍍鋅:熱鍍鋅是將鐵材質或其他金屬在加熱的鋅液中發生電解反應,使其表面形成一種厚厚的鋅表層。這種方法是通過將鋼制器件浸入熔融鋅液中,獲得金屬鍍層。抗腐蝕性冷鍍鋅:由于表面只有一層薄薄的鋅保護層,冷鍍鋅橋架的抗腐蝕性較差,容易發生腐蝕,導致鋅脫落。熱鍍鋅:熱鍍鋅橋架表面有一層厚厚的金屬保護層,不容易脫落,抗腐蝕性較強,使用壽命較長。使用范圍冷鍍鋅:冷鍍鋅一般用于鋼筋、護欄、扶手等地方。熱鍍鋅:熱鍍鋅一般用于通信塔、鐵路、公路結構件、船上結構件等需要高強度防腐的場合。工藝、厚度和工藝:冷鍍鋅是通過電鍍設備進行電化學沉積,熱鍍鋅是通過將鋼制器件浸入熔融鋅液中完成鍍鋅處理。厚度:熱鍍鋅橋架的鍍層厚度一般較厚,抗腐蝕能力強,冷鍍鋅橋架的鍍層厚度較薄,抗腐蝕能力較弱。:熱鍍鋅橋架質量較好,成本較高,因此也較高;冷鍍鋅橋架相對較低,但耐用性較差。表面特征冷鍍鋅橋架:表面較光滑,不易出現結塊等現象。熱鍍鋅橋架:外觀稍顯粗糙,會產生工藝水紋等特征。

1. The difference between cold (electric) galvanized bridge and hot-dip galvanized bridge is based on the principle of cold galvanizing: Cold galvanizing is the process of soaking or electrolyzing steel materials or products in a zinc solution, resulting in a relatively thin layer of zinc on the surface of the material or product. This method involves depositing a layer of zinc on steel components through electrochemical principles. Hot dip galvanizing: Hot dip galvanizing is the process of electrolyzing iron or other metals in heated zinc solution, forming a thick layer of zinc on its surface. This method involves immersing steel components in molten zinc to obtain a metal coating. Corrosion resistant cold dip galvanizing: Due to the thin layer of zinc protection on the surface, the corrosion resistance of cold dip galvanized cable trays is poor and prone to corrosion, resulting in zinc detachment. Hot dip galvanizing: The surface of the hot-dip galvanized bridge has a thick metal protective layer that is not easily peeled off, has strong corrosion resistance, and has a long service life. Scope of use: Cold galvanizing is generally used for steel bars, guardrails, handrails, and other places. Hot dip galvanizing: Hot dip galvanizing is generally used in communication towers, railways, highway structural components, ship structural components and other occasions that require high-strength anti-corrosion. Process, thickness, and price: Cold galvanizing is achieved through electrochemical deposition using electroplating equipment, while hot-dip galvanizing is achieved by immersing steel components in molten zinc solution for galvanizing treatment. Thickness: The coating thickness of hot-dip galvanized cable trays is generally thicker and has strong corrosion resistance, while the coating thickness of cold-dip galvanized cable trays is thinner and has weaker corrosion resistance. Price: Hot dip galvanized cable trays have better quality and higher costs, so the price is also higher; Cold galvanized cable trays are relatively inexpensive, but their durability is poor. Surface features: Cold galvanized bridge tray: The surface is relatively smooth and not prone to agglomeration and other phenomena. Hot dip galvanized cable tray: The appearance is slightly rough and may produce features such as process water marks.

熱鍍鋅橋架在抗腐蝕性、使用壽命和適用范圍上優于冷鍍鋅橋架,但較高;冷鍍鋅橋架則較低,適用于對防腐要求不高的場合。2、不銹鋼橋架和鍍鋅橋架的區別材料和防腐蝕性能不銹鋼橋架:由不銹鋼材料制成,具有優異的抗氧化和抗腐蝕性能。不銹鋼對潮濕、酸堿性環境具有很強的耐腐蝕性,特別適合用于室外或化工廠等腐蝕性較強的環境。

Hot dip galvanized cable trays are superior to cold dip galvanized cable trays in terms of corrosion resistance, service life, and applicability, but they are more expensive; Cold galvanized cable trays have a lower price and are suitable for occasions where anti-corrosion requirements are not high. 2. The difference in materials and corrosion resistance between stainless steel bridge and galvanized bridge. Stainless steel bridge: made of stainless steel material, it has excellent oxidation resistance and corrosion resistance. Stainless steel has strong corrosion resistance to humid and acidic environments, making it particularly suitable for outdoor or chemical plants with strong corrosiveness.

鍍鋅橋架:由普通鋼材經過熱浸鍍鋅工藝處理而成,表面鍍有一層鋅涂層以增加耐腐蝕性。雖然鍍鋅能提供一定程度的防腐蝕保護,但其耐腐蝕性能較弱,長期使用或極端環境下鋅涂層可能會磨損或受損。適用環境不銹鋼橋架:適用于高濕度、高鹽霧或化學腐蝕嚴重的環境,如沿海地區、化工廠、食品加工廠等。其優異的耐腐蝕性能使其在惡劣環境下仍能長期保持表面光潔和抗腐蝕性。

Galvanized bridge: Made of ordinary steel through hot-dip galvanizing process, with a layer of zinc coating on the surface to increase corrosion resistance. Although galvanizing can provide a certain degree of corrosion protection, its corrosion resistance is weak, and the zinc coating may wear or be damaged under long-term use or extreme environments. Applicable environment: Stainless steel cable tray: suitable for environments with high humidity, high salt spray, or severe chemical corrosion, such as coastal areas, chemical plants, food processing plants, etc. Its excellent corrosion resistance enables it to maintain a smooth surface and corrosion resistance for a long time even in harsh environments.

鍍鋅橋架:適用于一般室內和室外環境,其防腐蝕性能能夠滿足一般的電纜支架需求,但在特殊的腐蝕性環境下可能需要采取其他防腐蝕措施。維護需求不銹鋼橋架:由于其天然的抗腐蝕能力,基本無需維護,可以長時間使用且外觀持久美觀。鍍鋅橋架:需要定期檢查和維護,盡管可以通過熱浸鍍鋅、噴塑等防腐處理延長使用壽命,但仍需定期維護。經濟性不銹鋼橋架:初期投資較高,但幾乎不需要后續維護,使用壽命長,長遠來看可能更具經濟性。

Galvanized cable tray: suitable for general indoor and outdoor environments, its anti-corrosion performance can meet the general requirements of cable supports, but other anti-corrosion measures may need to be taken in special corrosive environments. Maintenance requirements for stainless steel cable trays: Due to their natural corrosion resistance, they require minimal maintenance and can be used for a long time with a long-lasting and aesthetically pleasing appearance. Galvanized cable tray: Regular inspection and maintenance are required. Although anti-corrosion treatments such as hot-dip galvanizing and spray coating can extend its service life, regular maintenance is still necessary. Economical stainless steel bridge: The initial investment is relatively high, but there is almost no need for subsequent maintenance, and the service life is long. In the long run, it may be more economical.

鍍鋅橋架:初期投資較低,但需要考慮長期的維護成本和可能的更換費用。

Galvanized cable tray: The initial investment is relatively low, but long-term maintenance costs and possible replacement costs need to be considered.

這兩種橋架的性能特點都差不多相同,都是具有不錯的耐腐蝕、耐老化、耐磨損性能,可以很好地保護電纜線路不受到傷害。但是由于不銹鋼的成本過高,所以不銹鋼橋架的采用率就沒有鍍鋅橋架的高,很多用戶選擇的都是鍍鋅橋架。

The performance characteristics of these two types of cable trays are almost the same, both having good corrosion resistance, aging resistance, and wear resistance, which can effectively protect cable lines from damage. However, due to the high cost of stainless steel, the adoption rate of stainless steel cable trays is not as high as that of galvanized cable trays, and many users choose galvanized cable trays.

在實際施工過程中,我們要根據負載能力、安裝環境、布局要求等方面選擇合適的橋架,以確保電纜系統的性、穩定性和經濟性。

In the actual construction process, we need to choose suitable cable trays based on load capacity, installation environment, layout requirements, etc., to ensure the safety, stability, and economy of the cable system.

本文由 山東電纜橋架 友情奉獻.更多有關的知識請點擊 http://m.bjxmj.com/ 真誠的態度.為您提供為的服務.更多有關的知識我們將會陸續向大家奉獻.敬請期待.

This article is a friendly contribution from Shandong Cable Bridge For more related knowledge, please click http://m.bjxmj.com/ Sincere attitude To provide you with comprehensive services We will gradually contribute more relevant knowledge to everyone Coming soon.